We work with companies that seek maximum precision and traceability in their quality control and production processes, providing Turnkey projects of metrology system integration, calibration, repair and on-site services.

Our equipment and services for quality control and dimensional inspection of:

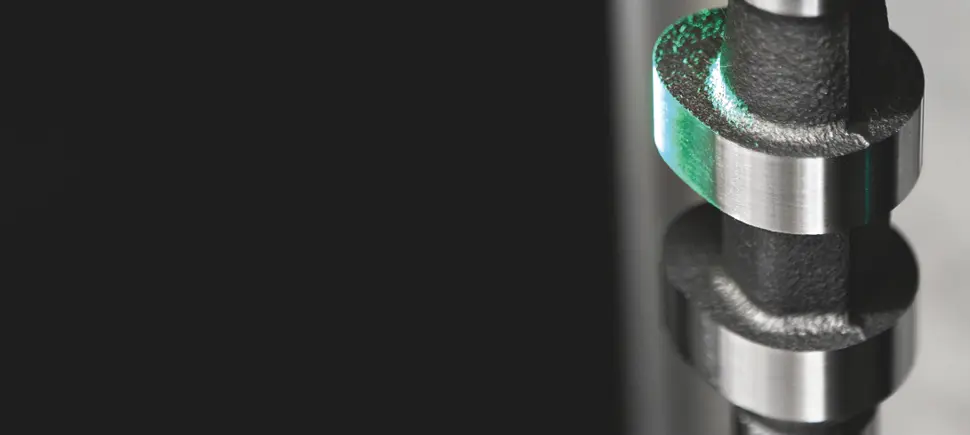

- Axles, shafts, crankshafts, and rotating components (diameters, concentricity).

- Transmission parts and assemblies (flatness, perpendicularity, and thicknesses).

- Powertrain and chassis components with critical tolerances.

- Gauges, with calibration interval scheduling.

- Micrometers (internal and external, digital), calipers, and 1D/2D height gauges selected for your critical tolerances.

Specialized equipment for cylindrical and symmetrical rotating parts:

- Axles, crankshafts, screws, threaded components and turned parts.

- Complete inspection in seconds, with digital recording of all dimensions and geometric tolerances.

- Direct integration with CNC machines for automatic parameter adjustment.

2D inspection for flat parts and complex profiles, flat cut parts or with irregular geometries:

- Plates, flanges, washers, supports, and precision components machined or laser-cut.

-

Direct comparison with CAD file and verification of multiple dimensions in a single capture.

Digital micrometers (internal/external) to verify diameters, thicknesses, and critical dimensions directly on the machine or in the inspection area.

High-precision calibrators with IP67 protection and data output for capture and statistical analysis.

1D and 2D height gauges to verify heights, flatness, perpendicularity, and internal/external distances with integration to SPC software.