DBLK offers solutions for precise measuring of components, to ensure reliable final products and optimize dimensional inspection times in production lines. From plastic housings and connectors to highly miniaturized metal parts, dimensional control and scrap reduction are guaranteed after integrating our products.

Our equipment and services are used for:

- Dimensional control of machined parts for electronic assemblies.

- Rapid measurement of plastic housings and machined parts for smartphones and laptops.

- Rapid and non-destructive measurement of housings, connectors, and microcomponents.

- Verification of tolerances in high-speed production lines.

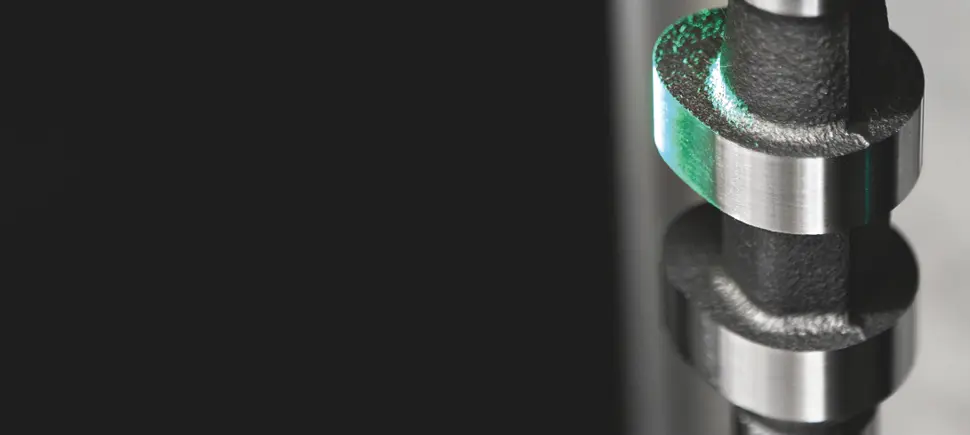

- Verification of diameters and thicknesses in connectors, pins, and terminals.

Speed is a key value in non-contact inspection, real-time statistical reports generated, ideal for high-volume series and eliminating human variability in Quality control. Integration with Quality, SPC, and ERP systems.

Digital micrometers (internal/external) to verify diameters, thicknesses, and critical dimensions directly on the machine or in the inspection area.

High-precision calibrators with IP67 protection and data output for capture and statistical analysis.

1D and 2D height gauges to verify heights, flatness, perpendicularity, and internal/external distances with integration to SPC software.