Schneider Messtechnik

Optical equipment and multisensor equipment for laboratories and workshops, which enhance competitiveness and production quality, with software options for different tasks and additives to optimize processes, for all budgets.

Standard products available in a wide range that can be customized upon request.

FAQ

If you are thinking about upgrading your equipment or investing in new production capabilities, you are probably wondering:

The optical measurement machines from Dr. Schneider Messtechnik use SAPHIR ©, a global metrological analysis software for Quality Control in the plant. Optional: Saphir U-Soft Solid ultra, M2, and M2.

Non-contact Metrology: Optical 2D | Non-contact metrology and scanning of irregular profiles and the "Z" axis, for production environments. |

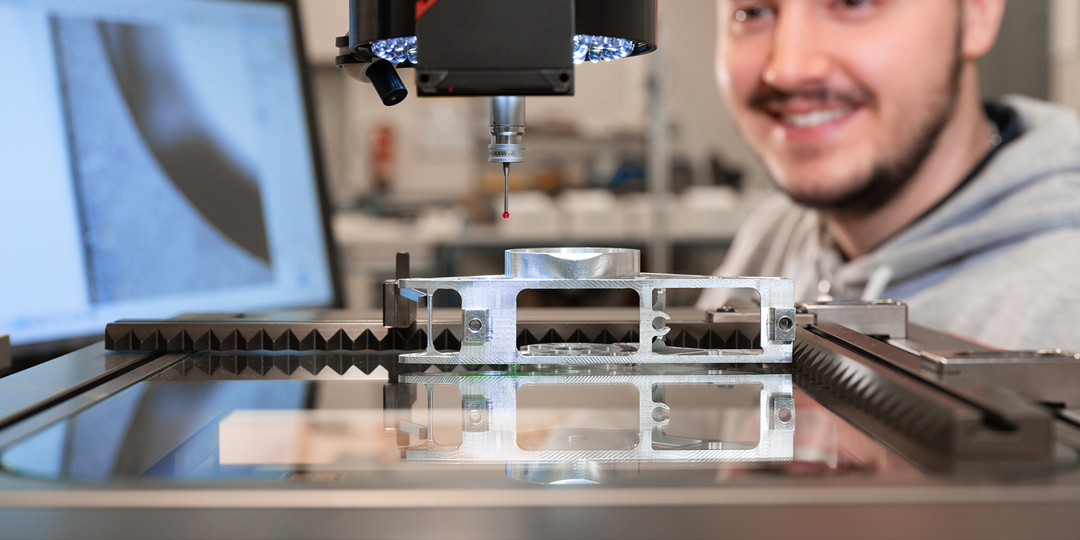

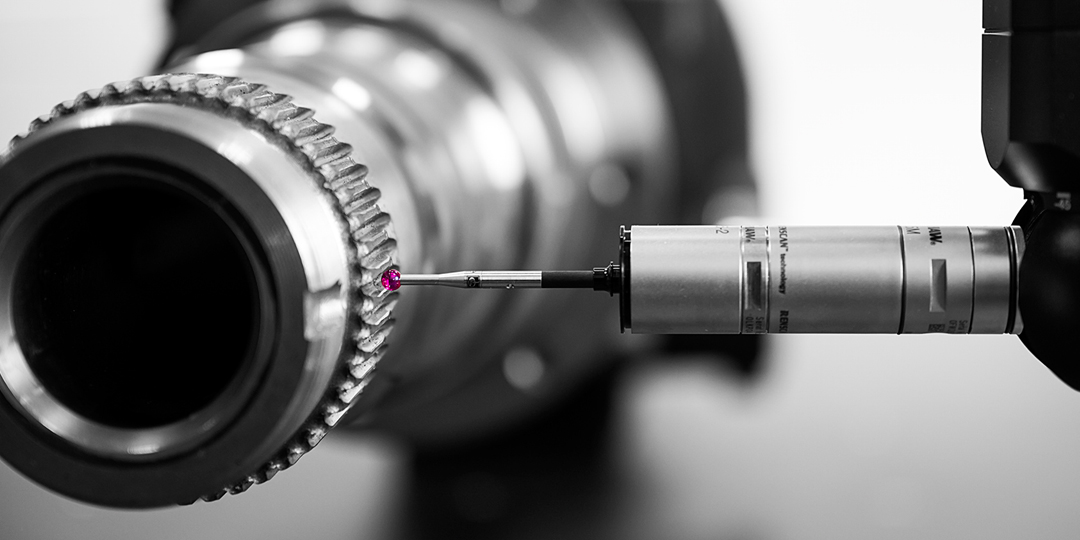

| Tactile coordinate Measuring Machine | All the most sought-after features in measurement software designed to operate from a wireless unit. |

WM1 Series | 2D multisensor equipment for use in production environments with CNC control availability to automate measurements in the 3 axes. |

PMS Series | For production environments, with configurations such as: touch probe and scanning sensor, for 3D measurements. Gantry-type measuring machines for greater stability of large parts. |