Vicivision

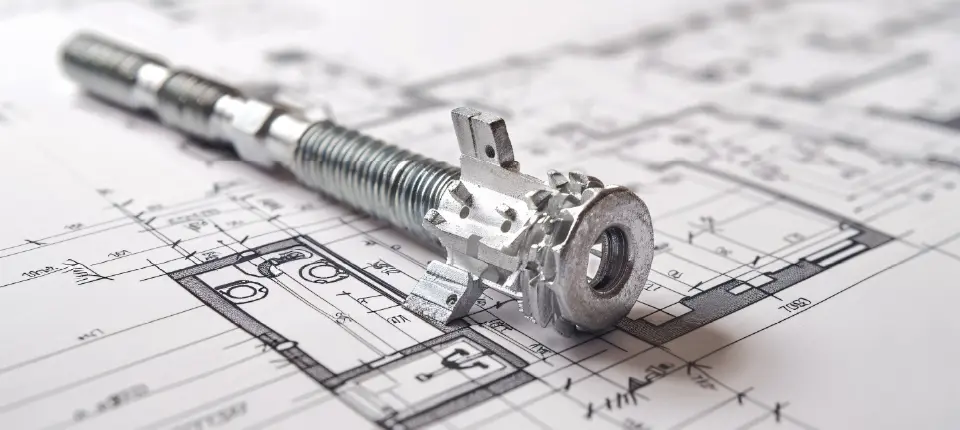

Optical measuring machines to automate the dimensional metrology inspection process of turned parts and with special functions for quality control in the production of camshafts, crankshafts, axles, valves, and screws, directly in the workshop.

FAQ

If you're thinking about upgrading your equipment or investing in new production capabilities, you're probably wondering:

Vicivision's optical measuring machines use Dream©, a software designed to simplify programming learning thanks to its graphical interface, which simplifies obtaining accurate measurements and real-time statistical reports. We offer training for program creation.

Vicivision Serie Techno | For turned parts with diameters from 40 to 180 mm and lengths from 300 to 2000 mm. Shafts, valves, and camshafts, among others. |

Vicivision Serie Prima | Parts that measure from 60 to 140 mm in diameter and 300 to 600 mm in length. Shafts, threads, and bolts, among others. |

Vicivision Serie X | Dental implants, biomedical components, watch parts and micromechanical components. |

Static measures:

|

Dynamic Measures:

|

Threads:

|

Nuts:

|

Tactile Measurements:

|

Profile measurements (optional):

|