DBLK provides instruments for dimensional control and optical metrology for the aerospace industry in Mexico, ensuring precision and traceability in the manufacturing of aeronautical and space components, even with extremely strict tolerances for machining processes. Additionally, DBLK offers consulting services, integration, training, certified equipment calibration, and preventive and corrective maintenance.

Our equipment and services are used in inspection and control of:

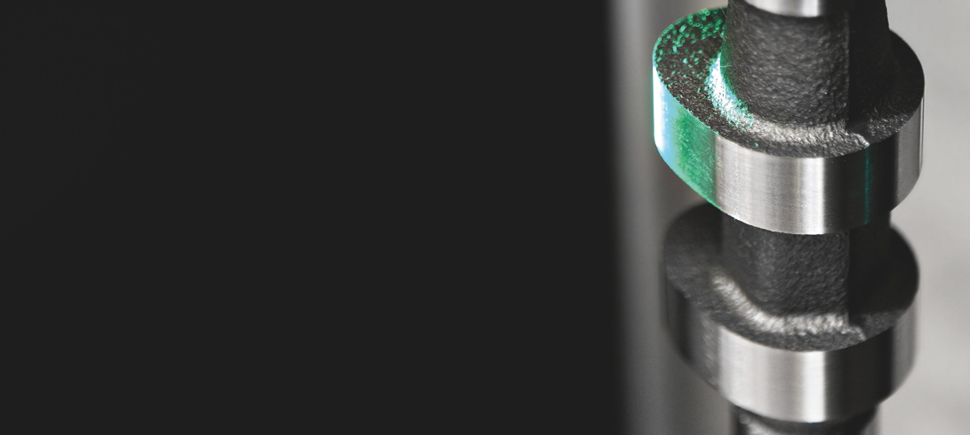

- Verification of critical engine components (shafts, bearings, turbines).

- Optical inspection of turned and milled parts with complex geometries.

- Non-contact measurement to reduce wear and prevent contamination.

- Digital traceability in compliance with AS9100 and international standards.

Specialized equipment for cylindrical and symmetrical rotating parts:

- Axles, crankshafts, worm screws, threaded components, and turned parts.

- Complete inspection in seconds, with digital recording of all dimensions and geometric tolerances.

- Direct integration with CNC machines for automatic parameter adjustment.

2D inspection for flat parts and complex profiles, flat cut parts or with irregular geometries:

- Plates, flanges, washers, supports, and precision components machined or laser-cut.

- Direct comparison with CAD file and verification of multiple dimensions in a single capture.

Digital micrometers (internal/external) to verify diameters, thicknesses, and critical dimensions directly on the machine or in the inspection area.

High-precision calibrators with IP67 protection and data output for capture and statistical analysis.

1D and 2D height gauges to verify heights, flatness, perpendicularity, and internal/external distances with integration to SPC software.